History of DOFER Tobacco Processing Company began at the end of the 1860s. Some of its units had already existed by the creation of the Independent Hungarian Tobacco Revenue in 1867, or were built after that. Tobacco receiving stations were established according to tobacco growing regions.

Processing Plant

Mártírok u. 51, H-5000 Szolnok, Hungary

Tel: +36 47 523 163 Fax: +36 56 425 474

Email: dofer@continentaltobacco.com

Between 1955 and 1957 an automated fermenting unit was built in Szolnok with a capacity of 3000 tons per year, which was doubled in 1966. In 1978, during an investment in capacity of 8000 tons per year, threshing line was installed in order to improve the quality of tobacco strips and increase the productivity of the processing.

The new picking line, finished product-press, tobacco silos and up-to-date technology installed in 1989 made it possible to process tobacco at European standards.

Continental Tobacco Group successfully acquired DOFER Tobacco Processor in 1997, during a privatisation process. In two years the new owner had the unit renovated and reorganised the farming background, too. This reorganisation had an effect on plant growing, as green houses for flooded trays were built. It also affected tobacco growing, as modern farming equipment were purchased, and tobacco fermenting, as the fermenting machinery was completely upgraded and additional new machines were installed.

The company provides work for more than one thousand families working in agriculture year by year, as well as professional advice on how to grow the best quality tobaccos.

DOFER is integrating 25% of the domestic tobacco growing at the moment.

Applied research on the biological grounds of tobacco growing and technological development activities to make technology better are tightly connected to basic activities.

By utilising species-comparison experiments those types of tobacco are sought which can be grown safely and economically.

In connection with introducing new growing techniques those practical works are carried out which are indispensable in the course of development. Studying our technological experiments is possible, while our experience is published via different information channels.

When composing the taste of a tobacco product, our master blenders mix tobacco leaves from 15-20 different locations. Thus, tobacco needed for our products, besides domestic tobacco, are imported from several different countries in the world from four continents; e.g. from Brazil, Argentina, Spain, Italy, Bulgaria, Indonesia and Turkey.

The development of the Hungarian manufacturing industry began in the 1860’s, and was adjusted to the needs of the market of the Austro-Hungarian Monarchy. Agriculturally based industries – sugar works, distillation plants and mills – were most successful. Within twenty years, there were 21 tobacco factories running within the borders of Hungary.

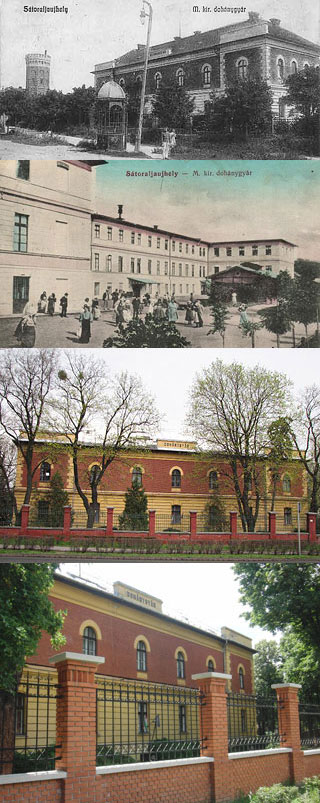

Continental Tobacco Corp. Satoraljaujhely Factory

Dohány u. 1-3 H-3980 Sátoraljaújhely, Hungary

Tel: +36 47 523-160, Fax: +36 47 321 228

E-mail: factory@continentaltobacco.com

Tobacco product production started in Sátoraljaújhely in 1891 with 80 workers. Smoking cigars was the ordinary way of smoking in that era, and the labor-intensive process of producing cigars accompanied by the increasing demand on this product prompted the Hungarian Royal Revenue in 1892 to increase the capacity of the factory.

The new factory started the production in the autumn of 1894 with 305 female and 11 male workers; in 1897 the manpower reached 620 workers.

Change of smoking habits promoted the production of hand-made cigarettes, and further mechanization prompted significant growth in production at the end of the 1920’s. After 1932, the factory only produced cigarettes.

1945 and 1985 the factory played a significant role in satisfying the demands of the Hungarian domestic tobacco market.

In the course of the privatization (28 July 1992) the RJ Reynolds Tobacco Company (RJR), the second largest American multinational tobacco company, became the principal shareholder after purchasing the stocks of the AoSP. The management of RJR launched the company’s renowned products (Camel, Winston, Salem) on the Hungarian market beside producing the traditional domestic non-filter brands – Munkás and Kossuth. The modernization of the production line became necessary in order to fulfill the quality requirements of RJR.

In 1997 the management of RJR decided to withdraw from Hungary and sold the shares of Sátoraljaújhely Tobacco Factory to Continental Tobacco Group.

On 1 January 1998, Continental Tobacco Corporation became the owner of the traditional tobacco factory. Since the acquisition Continental invested more than 20 million Euros in primary and secondary machinery, building and people and turned the factory into a “total tobacco” manufacturing plant. The factory is certified according to ISO 9001:2000 and committed to production meeting the highest industry standards.

These investments and continued commitment to progress assure diversified production of the highest quality tobacco products for CTC consumers.

After the successful market entry in Hungary our group has started to consciously build its international market presence. Though the majority of our current international business is realised within the EU, we serve clients in over 25 counrtries even as far as Japan.

Continental Tobacco Int’l Sales

Dohany u 1-3, Satoraljaujhely, H-3980 Hungary

Tel: + 36 47 523 167

E-mail: sales@continentaltobacco.com

In order to meet the market needs at our best, our four subsidiaries in Europe (Germany, Italy, Slovakia and Romania) are primarily engaged in the sales of our own brands.

As a result of strategic partnerships we also became the supplier of numerous private label projects. The range covers from the price sensitive value category to premium natural cigarettes, small filter cigarillos wrapped in natural leaf or ecocigarillos, or RYO and MYO tobaccos and filter cigarette tubes.

We are proud of the dynamic growth of our partners and still, restlelessy looking for new opportunities and challanges to prove our capabilities as a solution provider.